Products & Solutions

Discover our extensive portfolio of bespoke products, spread over diverse industry divisions

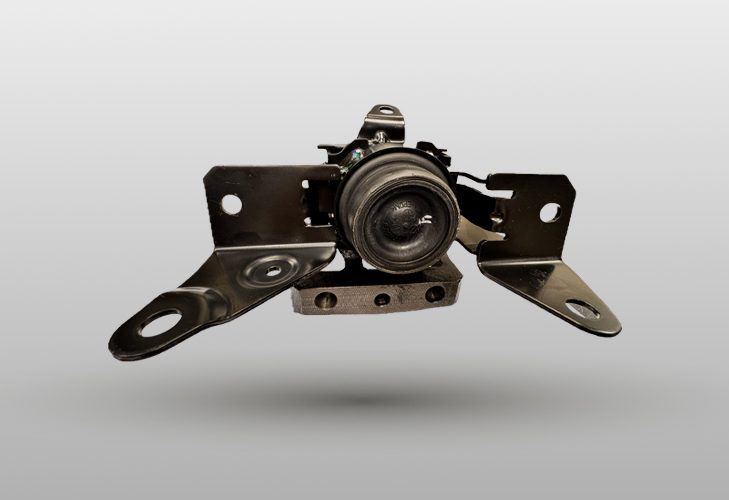

Engine Mount

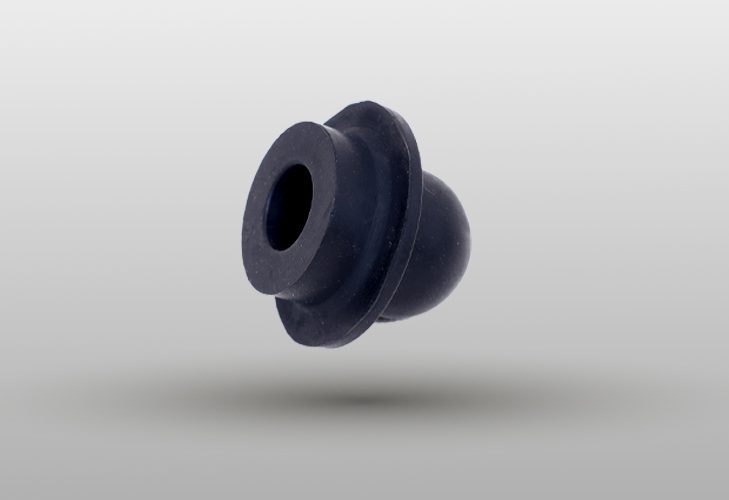

Suspension Bush

Bushes are used to control the movement of the joints in the suspension, helping to absorb shocks from the road which connect the suspension of the vehicle to its frame. The bushes act as vibration covers that lessen the force transmitted from one moving component to another and isolate from noise in the vehicle. These bushes are applied in vehicle suspension system in front as well as rear portion to make comfortable ride and enhance overall life of vehicle. Many types of bushes are used for solution like straight outer tube, outer less bush & flange type bush as per vehicle stiffness requirement.

Strut Mount (Top Mount)

Bump Stopper

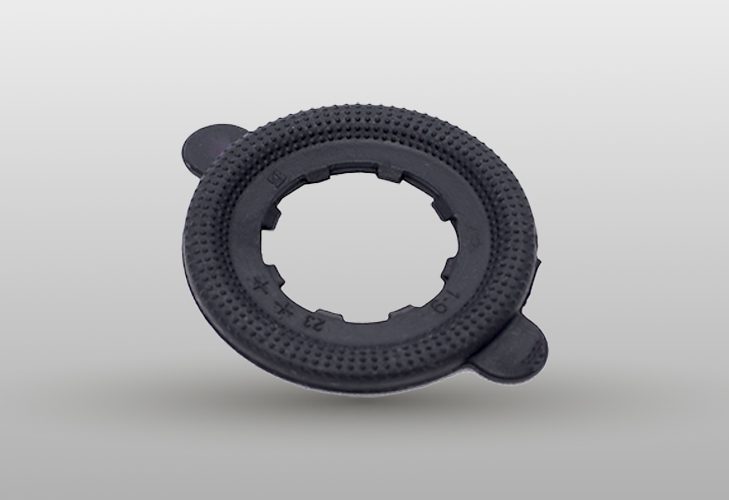

Spring Seat

Stab Bush

Reduces the road noise produced by your vehicle. At the same time, it helps in absorbing bumps from the cracks on the roads. Assisting in providing a soft and smooth ride, they also offer protection to vehicle’s body from rolling. Settled on the undercarriage of the vehicles, they eliminate trouble with body roll, when the vehicle takes turns.

Torsional Damper

Torsional Vibration Dampers absorb rotational vibrations in internal combustion engines. The dampers are particularly effective in conjunction with decoupled pulleys, which keep crankshaft irregularities away from the belt drive and auxiliaries. In fuel-efficient start-stop systems, they eliminate the effects of an engine that is constantly starting and stopping.

Coupling Rubber

Cabin Mount

Centre Bearing Support

Hydro Engine Mount

Hydraulic engine mounts are made of rubber, and they feature a hollow center filled with hydraulic fluid, usually a glycol/water mixture. As well as supporting the engine, the mounts must absorb two main types of vibration:

Low frequency vibration that comes from shock excitation – accelerating or braking hard and driving on rough surfaces for example.

High frequency vibration that comes from unbalanced engine forces, such as from firing pulses or any mass imbalance in the rotating or reciprocal engine parts.

Torque Rod

Torque rods or torque roll restrictors dampen the impact of torque by restricting motor roll during load transfer. They also tackle the challenges derived from recuperation functions. In addition to restricting motor roll, they prevent vibration and noise transfer from the motor block to the chassis.